Isolite is known to be the best thermal, fire-resisting, sound-proof insulator, used for ceiling, roofs, walls, partitions, roads, water and petroleum tanks, whether underground, or on the surface, etc.

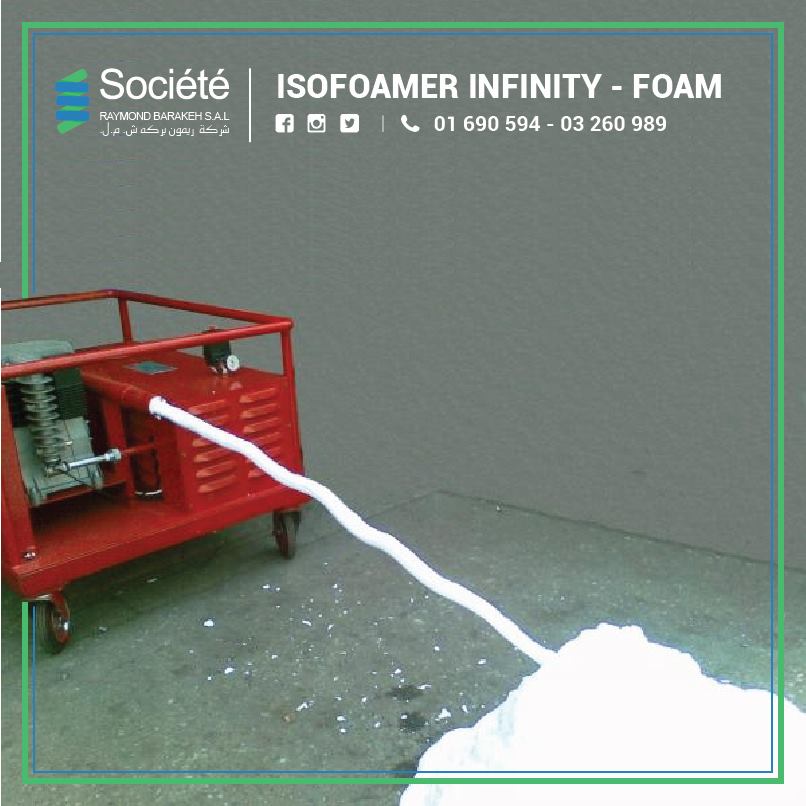

Isolite is a light-weight cellular foam concrete made of fine sand, cement, water, and a special chemical which causes air cells to spread evenly. This resulting mixture can be prepared mechanically on the spot, and to the requested density.

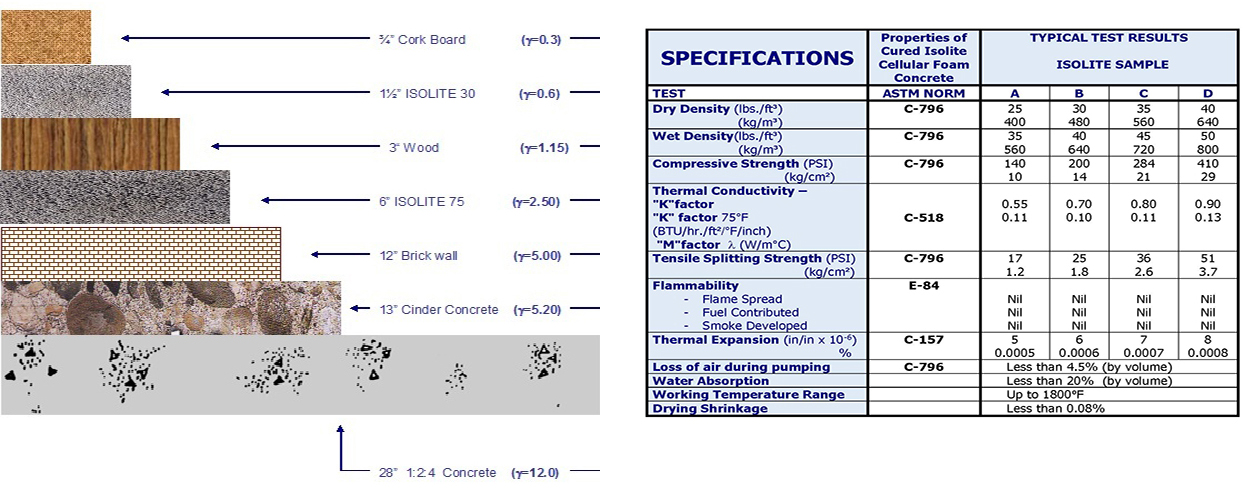

Isolite can be produced at several densities varying between 300 Kg. and 1400 Kg/cu.m. (between 19 lbs. and 90 lbs./cu.ft.) to which corresponds a variation of mechanical resistance, as well as thermal conductivity coefficient .

Thermal Insulator

Lightweight

Acoustic Insulator

Eco-friendly

Resistant to Chemicals

Isolite is a lightweight cellular foam concrete made of filler cement, sand &/or fly ash…, and a foaming agent which produces air cells or foam.

Voids, Roofs, Walls, Roads, Partitions, Water tanks, Petroleum tanks, Artificial stones, Blocks, Reversed beams, Floors.

Eco-friendly, Excellent fire resistant properties, Lightweight., Easy to cut, Non corrosive, Thermal insulator, Sound-proof, Resistant to chemicals, Impermeable, Free flowing, self-leveling, Once placed requires no maintenance, Excellent resistance to earthquake, Does not impose lateral loads, Excellent fire resistant properties, Highly cost effective, Non-hazardous, Reliable quality control.

Foam concrete is a versatile material. Its ability to flow easily under its self-weight has led to its use in void filling, reversed beams, old sewerage pipes, wells, cellars, buildings basements, storage tanks, tunnels and subways.

It is used too as insulating material on roofs, in housing foundations and floors. Its inherent fire resistance has also been exploited in a wide range of uses. Foamed concrete has also been used in bridge foundations

Other applications include precast elements, in raft foundations of houses, as a foundation-layer for sports fields and athletic tracks, backfilling the voids behind tunnel linings.

Foam concrete has two benefits when used for roofing. It provides a high degree of thermal insulation and used to lay a flat roof to falls, i.e. to provide a slope for drainage. Foam concrete is also much lighter than slopes made from mortar screeds. This means that a roof with a slope made of foamed concrete imposes a lower loading on the structure of the building.

We have been in the foam concrete business since 1964.

Foam concrete may well be used in the runway organization system, shipping dock collision wall etc.

The service life of foam concrete is nearly similar to ordinary concrete.

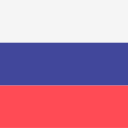

The minimum output of machinery produced by our company is 6 cubic m³per hour and the maximum 48 cubic m³ per hour.

Our Isolite-RTUC foaming agent is sold in 2 different types: Dissolved & Concentrated. Isolite is well known in the market since it’s first launching in 1964.

+9613260989

+9611690594

Bauchrieh - Industrial City Sector 7

40, Street 86 Beirut - LEBANON